Pipes are cylindrical conduits used to transport fluids

(liquids, gases, and sometimes solids) from one location to another. Unlike

tubes, pipes are typically specified by their internal diameter (ID) rather

than their outer diameter, and they are integral to a wide variety of systems,

including plumbing, gas distribution, oil transportation, and industrial

processes. Here’s a detailed overview of pipes:

1. Materials:

- Steel Pipes:

- Carbon Steel: Commonly used in industrial and

construction applications due to its strength and durability. It’s often

used for transporting water, gas, and oil.

- Stainless Steel: Highly resistant to corrosion and heat,

making it ideal for use in chemical plants, food processing, and other

environments where hygiene and resistance to corrosive substances are

critical.

- Galvanized Steel: Steel pipes coated with zinc to prevent

corrosion, often used in plumbing and outdoor applications.

- Copper Pipes:

- Widely used in plumbing due to its excellent

corrosion resistance and thermal conductivity. Commonly used for hot and

cold water supply, heating systems, and refrigeration lines.

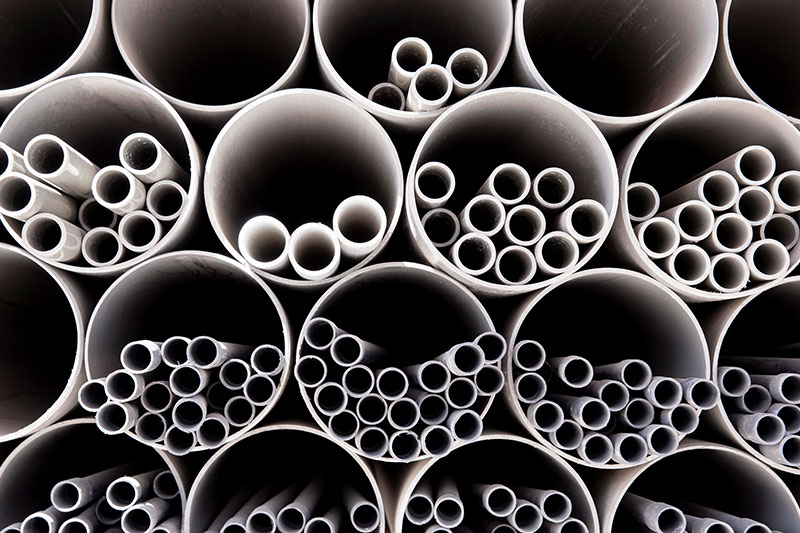

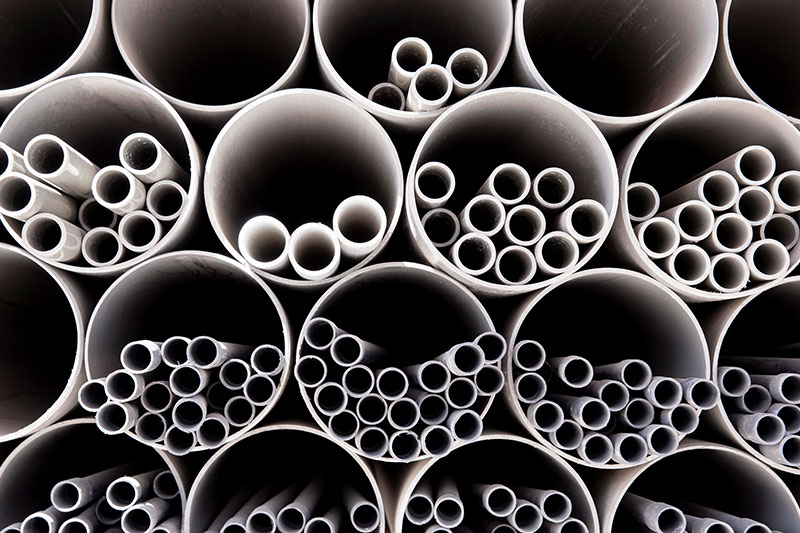

- Plastic Pipes:

- PVC (Polyvinyl Chloride): Popular in residential plumbing for waste

water and drainage systems, as well as cold water supply lines. PVC pipes

are lightweight, resistant to chemicals, and easy to install.

- CPVC (Chlorinated Polyvinyl Chloride): Similar to PVC but can handle higher

temperatures, making it suitable for hot water supply.

- PEX (Cross-linked Polyethylene): Flexible and easy to install, PEX is often

used in water supply lines and radiant heating systems.

- HDPE (High-Density Polyethylene): Used for water mains, gas distribution, and

industrial applications due to its high impact resistance and

flexibility.

- Concrete Pipes:

- Used for large-diameter water mains, storm

drains, and sewer systems. Reinforced concrete pipes (RCP) are often used

where high strength is required.

- Cast Iron Pipes:

- Traditionally used for drainage and sewer

systems, especially in older buildings. Cast iron is durable and

excellent at noise dampening.

- Ductile Iron Pipes:

- A type of cast iron that is more flexible and

impact-resistant, often used in water and sewer applications due to its

strength and durability.

- Composite Pipes:

- Made from a combination of materials, such as

fiber-reinforced polymers, these pipes offer strength, lightweight

properties, and resistance to corrosion.

2. Types of Pipes:

- Seamless Pipes:

- Manufactured from a solid billet, these pipes

have no welded seam, making them ideal for high-pressure applications

like oil and gas pipelines, chemical plants, and power generation.

- Welded Pipes:

- Made by rolling a flat piece of metal and

welding the edges together. While they are generally less expensive than

seamless pipes, they are used in a wide range of applications, from water

distribution to gas pipelines.

- Rigid Pipes:

- Typically made of metal, concrete, or rigid

plastic, these pipes are used where strength and durability are

essential, such as in underground water mains and industrial systems.

- Flexible Pipes:

- Made from materials like PEX or HDPE, these

pipes can bend without breaking, making them useful in situations where

the pipe must navigate around obstacles or absorb movement.

3. Applications:

- Plumbing:

- Pipes are essential for the distribution of

potable water, removal of wastewater, and delivery of hot water in

residential, commercial, and industrial buildings.

- Gas Distribution:

- Pipes made from materials like steel or HDPE

are used to transport natural gas from production sites to homes and

businesses.

- Oil and Gas Pipelines:

- Large-diameter steel pipes are used to

transport crude oil, refined petroleum products, and natural gas over

long distances, often across countries.

- Industrial Processes:

- Pipes transport various fluids and gases

within industrial plants, including chemicals, steam, and compressed air.

Stainless steel and alloy pipes are often used in chemical plants due to

their resistance to corrosion and high temperatures.

- HVAC (Heating, Ventilation, and Air

Conditioning):

- Pipes are used to circulate air,

refrigerants, and heated water within buildings, ensuring a comfortable

indoor environment.

- Drainage and Sewage:

- Pipes made of materials like PVC, cast iron,

and concrete are used to carry wastewater away from buildings and into

the sewer system or treatment facilities.

- Fire Protection Systems:

- Pipes are a critical component of sprinkler

systems, which distribute water to extinguish fires in residential,

commercial, and industrial buildings.

4. Manufacturing

Processes:

- Extrusion (for Plastic Pipes): Involves pushing molten plastic through a

die to create a continuous pipe of the desired diameter.

- Casting (for Iron Pipes): Molten iron is poured into molds to create

pipes of specific dimensions.

- Welding (for Steel Pipes): Steel sheets are rolled into shape and

welded along the seam to form a pipe.

- Drawing (for Seamless Pipes): A solid billet is heated and then drawn over

a mandrel to create a seamless pipe.

5. Pipe Fittings and

Connections:

- Elbows: Used to change the direction of the pipe run.

- Tees:

Allow for branching off from the main pipe.

- Reducers: Used to connect pipes of different diameters.

- Couplings: Connect two pipes of the same diameter.

- Flanges: Used to connect pipes, valves, and pumps, providing easy access

for inspection and modification.

- Valves: Control the flow of fluids through the pipes.

6. Coatings and Linings:

- Galvanization: Steel pipes are often coated with zinc to

prevent corrosion.

- Epoxy Coatings: Applied inside pipes to prevent corrosion

and improve flow characteristics, commonly used in water and wastewater

pipes.

- Bituminous Coatings: Often used on the exterior of buried pipes

to prevent corrosion from soil and moisture.

7. Standards and

Quality Control:

- Testing: Pipes undergo pressure testing, non-destructive testing (like

X-rays for welds), and hydrostatic testing to ensure they meet the

required standards.

- Standards: Pipes are manufactured to standards such as ASTM, ISO, and API,

which dictate the material, dimensions, and performance characteristics.

Pipes are fundamental

components in many infrastructure systems, ensuring the safe and efficient

transportation of fluids and gases. Their selection depends on factors like the

type of fluid being transported, pressure requirements, environmental conditions,

and regulatory standards.